动态测量功能适用于手动在工件上采点, 软件从导入的数模上自动查找最近测点作为测量点的理论值, 在动态测量界面实时显示偏差值, 常应用于检测的同时调整模具检具等。

1.动态点

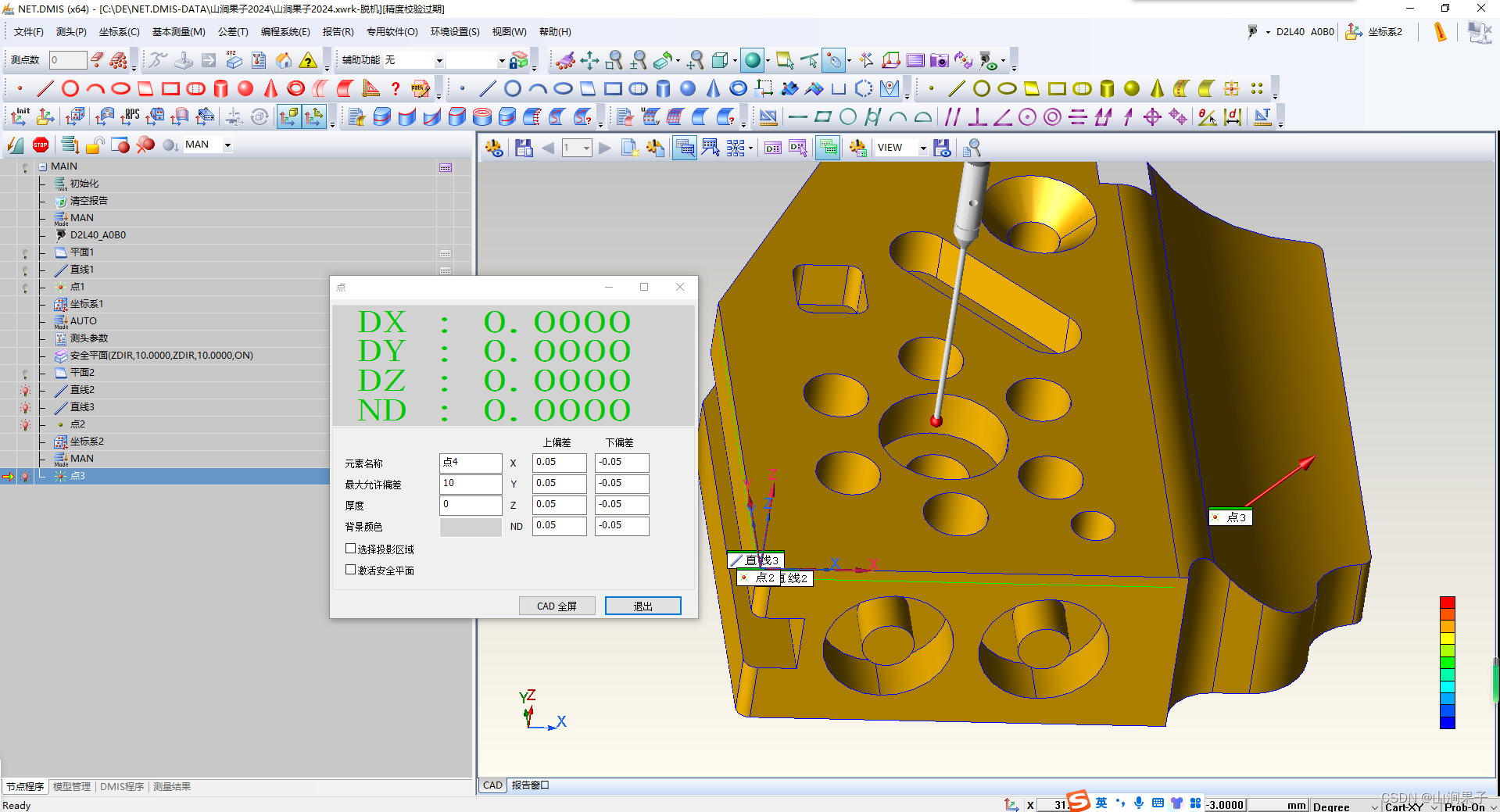

通过手动采点, 在模型上自动查找最近测点, 作为测量点的理论值, 并用该理论点的矢量方向进行测头补偿。

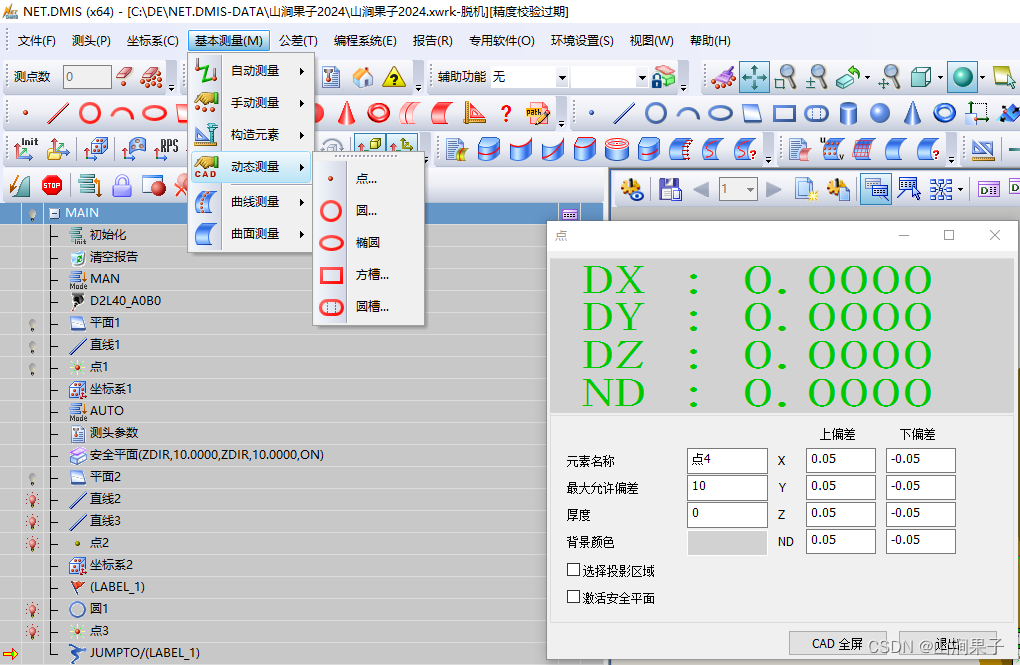

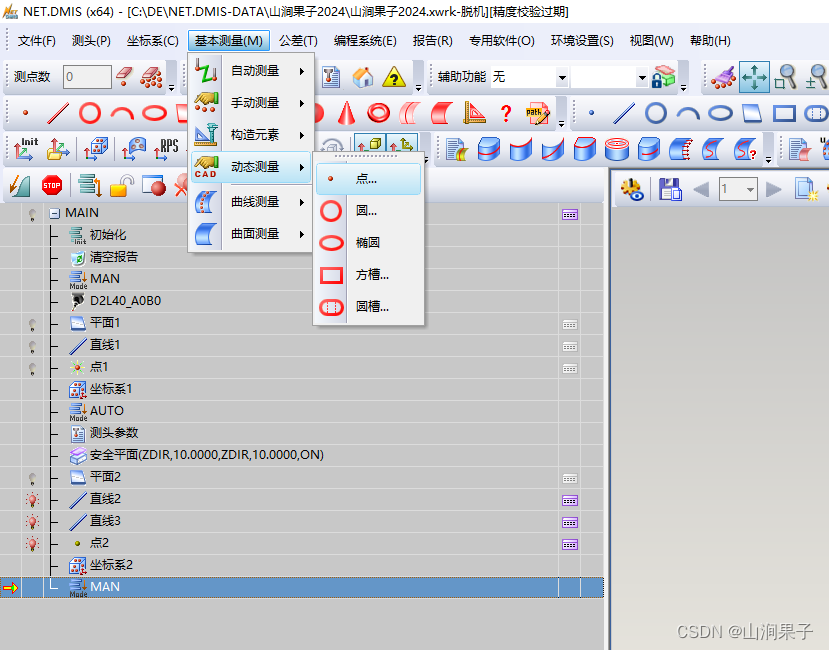

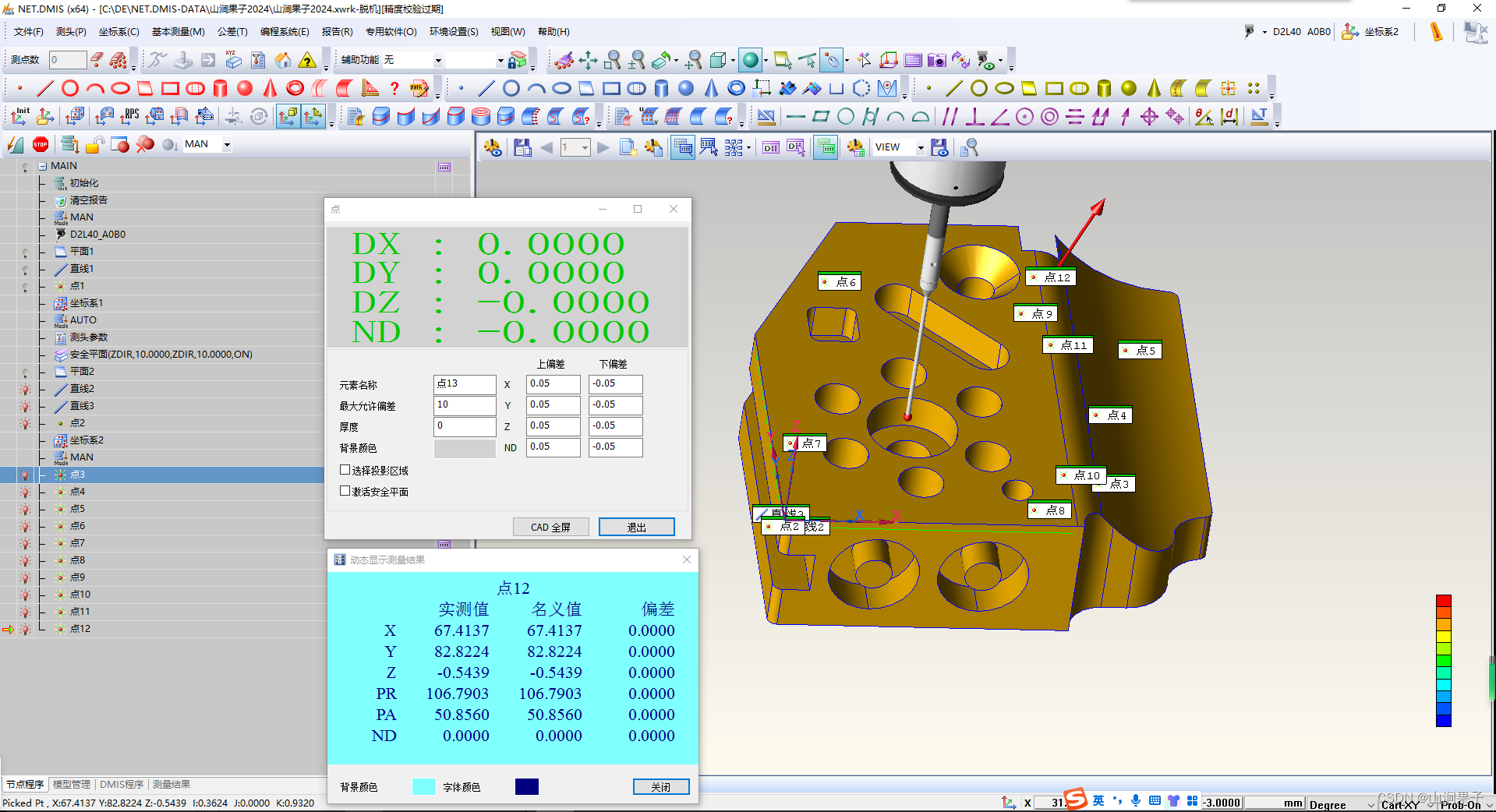

1.导入模型, 建立与模型坐标系一样的工件坐标系, 点击【 基本测量】 →【 动态点】, 弹出如下图所示界面:

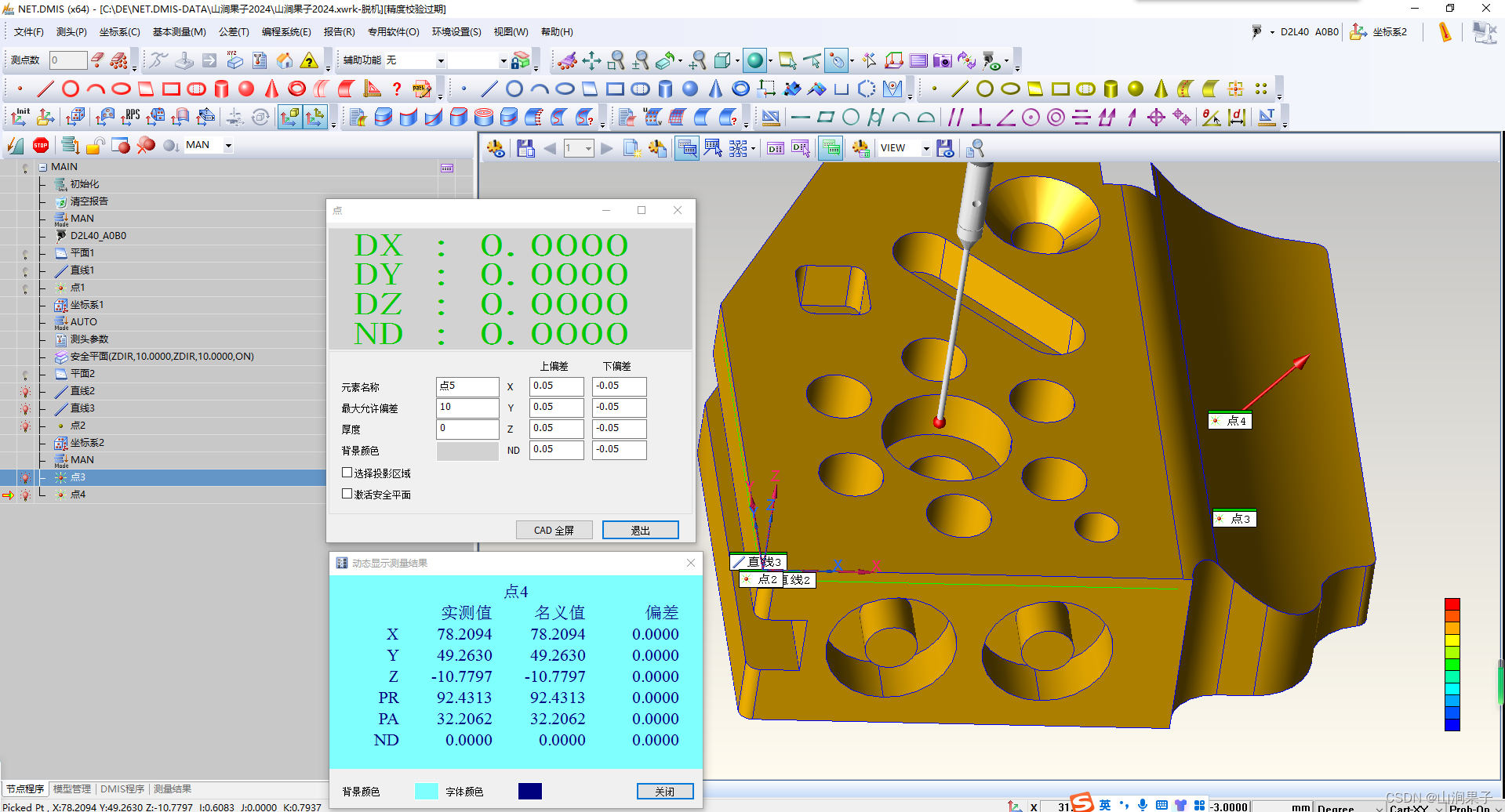

2.这样就可以用操作盒在工件上测量点,并直接显示数模上的理论值和测量的实测值的偏差~

动态显示测量结果

这个功能在测量钣金件看型面点T值时非常有效~

因为有时偏差非常大,测不到,还需要给出结果,就可以在零件上测点从数模抓取理论值,用的就是这种方法~

$$ NET_DMIS_20160720

$$ MADE IN DE 2023-2-24 10:47:9

INCLUD/DMIS,'NET_DMIS_DEFINES.DMI'

INCLUD/DMIS,'VARDEFINE'

DMESW/COMAND,'PROBE_VAL/INIT'

UNITS/MM,ANGDEC

D(MACHINE)=DATSET/MCS

DMESW/COMAND,'COORDSYS/ALIGN'

WKPLAN/XYPLAN

PRCOMP/ON

PRCOMP/ON

FEDRAT/POSVEL,MMPS,300.0000

ACLRAT/POSACL,MMPSS,100.0000

FEDRAT/MESVEL,MMPS,20.0000

ACLRAT/MESACL,MMPSS,100.0000

SNSET/RETRCT,2.0000

SNSET/SEARCH,5.0000

SNSET/APPRCH,2.0000

DMESW/COMAND,'SNSET/MANRETRCT,1.0000'

DMESW/COMAND,'REPORT/CLEAR'

MODE/MAN

DID(D2L40)=DEVICE/STOR,'D2L40'

OPEN/DID(D2L40),SNS

S(A0B0)=SNSDEF/PROBE,INDEX,POL,0.0,0.0,0.0000,0.0000,1.0000,189.6500,2.0000

SNSLCT/SA(A0B0)

GEOALG/PLANE,LSTSQR

F(平面1)=FEAT/PLANE,CART,20.9373,23.4675,0,0,0,1.00000000

MEAS/PLANE,F(平面1),3

PTMEAS/CART,2.3296,57.1819,0,0,0,1.00000000

PTMEAS/CART,1.6972,7.2497,0,0,0,1.00000000

PTMEAS/CART,58.7850,5.9709,0,0,0,1.00000000

ENDMES

SNSET/DEPTH,0

DMESW/COMAND,'CONST/SET_PROJ_VEC,FA(平面1),1'

F(直线1)=FEAT/LINE,UNBND,CART,4.4714,0,-2.3983,0.99996453,0,0.00842198,0,-1.00000000,0

MEAS/LINE,F(直线1),2

PTMEAS/CART,4.4714,0,-2.1493,0,-1.00000000,0

PTMEAS/CART,63.6074,0,-2.1493,0,-1.00000000,0

ENDMES

F(点1)=FEAT/POINT,CART,0,5.1768,-2.9682,-1.00000000,0,0

MEAS/POINT,COMP,DME,F(点1),1

PTMEAS/CART,0,5.1768,-2.9682,-1.00000000,0,0

ENDMES

DATDEF/F(平面1),DAT(A_平面1)

D(坐标系1_S)=DATSET/DAT(A_平面1),ZDIR

D(坐标系1_R)=ROTATE/ZAXIS,FA(直线1),XDIR

D(坐标系1_T)=TRANS/ZORIG,FA(平面1)

D(坐标系1_T)=TRANS/YORIG,FA(直线1)

D(坐标系1_T)=TRANS/XORIG,FA(点1)

DMESW/COMAND,'COORDSYS/CAD=PART'

SAVE/DA(坐标系1)

MODE/AUTO,PROG,MAN

SNSET/RETRCT,2.0000

SNSET/APPRCH,2.0000

DMESW/COMAND,'CLEARP/ZDIR,10.0000,ZDIR,10.0000,ON'

F(平面2)=FEAT/PLANE,CART,32.8669,46.7024,0,0,0,1.00000000

CALL/EXTERN,DMIS,M(NETDMIS_AUTO_PLANEPOINTS_1006),AUTOFIGURE,F(平面2),PLANE,CART,LSTSQR,32.8669,46.7024,$

0,0,0,1.00000000,FALSE,FALSE,FALSE,10.0000,"CUR",TRUE,FALSE,POINTS,'7,2.4722,8.4595,0,0,0,1.00000000,$

4.3713,61.8746,0,0,0,1.00000000,22.1788,94.0318,0,0,0,1.00000000,58.2235,95.5053,0,0,0,1.00000000,60.1273,$

55.5342,0,0,0,1.00000000,59.8803,3.8610,0,0,0,1.00000000,22.8146,7.6502,0,0,0,1.00000000',TOUCH,0.3000,$

XYPLAN

F(直线2)=FEAT/LINE,BND,CART,4.0000,0,-2.0000,64.0000,0,-2.0000,0,-1.00000000,0

CALL/EXTERN,DMIS,M(NETDMIS_AUTO_LINE_1007),AUTOFIGURE,F(直线2),LINE_BND,CART,4.0000,0,-2.0000,1.00000000,$

0,0,60.0000,FALSE,FALSE,FALSE,10.0000,"CUR",TRUE,FALSE,0,-1.00000000,0,4,0,0,0,TOUCH,0.3000,XYPLAN,0,$

0,LINE,"","","EXT1","EXT2","EXT3",ENDCAL

F(直线3)=FEAT/LINE,BND,CART,0,4.0000,-2.0000,0,59.0000,-2.0000,-1.00000000,0,0

CALL/EXTERN,DMIS,M(NETDMIS_AUTO_LINE_1007),AUTOFIGURE,F(直线3),LINE_BND,CART,0,4.0000,-2.0000,0,1.00000000,$

0,55.0000,FALSE,FALSE,FALSE,10.0000,"CUR",TRUE,FALSE,-1.00000000,0,0,4,0,0,0,TOUCH,0.3000,XYPLAN,0,0,$

LINE,"","","EXT1","EXT2","EXT3",ENDCAL

F(点2)=FEAT/POINT,CART,0,0,-2.0000,0,0,-1.00000000

CONST/POINT,F(点2),INTOF,FA(直线2),FA(直线3)

DATDEF/F(平面2),DAT(A_平面2)

D(坐标系2_S)=DATSET/DAT(A_平面2),ZDIR

D(坐标系2_R)=ROTATE/ZAXIS,FA(直线2),XDIR

D(坐标系2_T)=TRANS/XORIG,FA(点2),YORIG,FA(点2)

D(坐标系2_T)=TRANS/ZORIG,FA(平面2)

SAVE/DA(坐标系2)

MODE/MAN

F(点3)=FEAT/POINT,CART,76.0558,24.5406,-8.9878,0.669836,0,0.742509

MEAS/POINT,COMP,DME,F(点3),1

PTMEAS/CART,76.0558,24.5406,-8.9878,0.669836,0,0.742509

ENDMES

F(点4)=FEAT/POINT,CART,78.2094,49.2630,-10.7797,0.608302,0,0.793706

MEAS/POINT,COMP,DME,F(点4),1

PTMEAS/CART,78.2094,49.2630,-10.7797,0.608302,0,0.793706

ENDMES

F(点5)=FEAT/POINT,CART,88.2821,77.2099,-16.1536,0.320512,0,0.947244

MEAS/POINT,COMP,DME,F(点5),1

PTMEAS/CART,88.2821,77.2099,-16.1536,0.320512,0,0.947244

ENDMES

F(点6)=FEAT/POINT,CART,20.4639,79.1436,0.0000,0,0,1.000000

MEAS/POINT,COMP,DME,F(点6),1

PTMEAS/CART,20.4639,79.1436,0.0000,0,0,1.000000

ENDMES

F(点7)=FEAT/POINT,CART,7.2337,25.3562,0.0000,0,0,1.000000

MEAS/POINT,COMP,DME,F(点7),1

PTMEAS/CART,7.2337,25.3562,0.0000,0,0,1.000000

ENDMES

F(点8)=FEAT/POINT,CART,58.8168,5.0493,0.0000,0,0,1.000000

MEAS/POINT,COMP,DME,F(点8),1

PTMEAS/CART,58.8168,5.0493,0.0000,0,0,1.000000

ENDMES

F(点9)=FEAT/POINT,CART,62.6264,70.0748,0.0000,0,0,1.000000

MEAS/POINT,COMP,DME,F(点9),1

PTMEAS/CART,62.6264,70.0748,0.0000,0,0,1.000000

ENDMES

F(点10)=FEAT/POINT,CART,67.1319,17.2081,-0.4404,0.327198,0,0.944956

MEAS/POINT,COMP,DME,F(点10),1

PTMEAS/CART,67.1319,17.2081,-0.4404,0.327198,0,0.944956

ENDMES

F(点11)=FEAT/POINT,CART,68.9867,61.3695,-1.3669,0.559048,0,0.829135

MEAS/POINT,COMP,DME,F(点11),1

PTMEAS/CART,68.9867,61.3695,-1.3669,0.559048,0,0.829135

ENDMES

F(点12)=FEAT/POINT,CART,67.4137,82.8224,-0.5439,0.362429,0,0.932011

MEAS/POINT,COMP,DME,F(点12),1

PTMEAS/CART,67.4137,82.8224,-0.5439,0.362429,0,0.932011

ENDMES

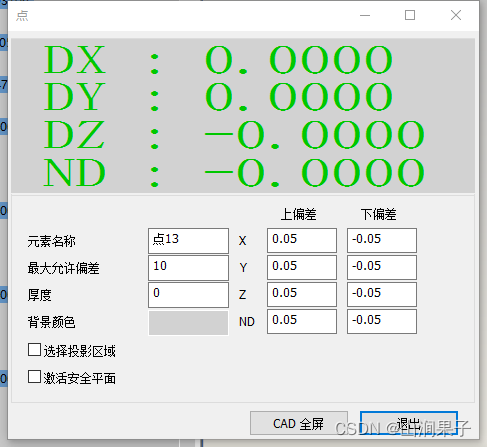

1.界面参数介绍:

“ DX, DY, DZ, ND” 为实测与理论坐标值相比所得实际偏差值。 DX, DY, DZ, ND 随采点状态随时更新。

“ 元素名称” 使用默认名称或者自定义动态点的名称。

“ 最大允许偏差” 为根据实测值在模型上搜索理论值的一个搜索范围, 若实测值与理论值之间的偏差值大于输入的数值, 则与实测值对应的名义值将不能被搜索到, 这时软件会提示“ 坐标系不正确或采点误差较大”。

“ 厚度” 厚度补偿时补偿名义值。

“ 选择投影区域” 指定测点在模型上读取名义值的投影区域位置。 使用时在采点前先勾选,然后切换到“ 选择面” 在模型上拾取投影面或先从模型上拾取投影面后勾选。 若不选择, 软件自动判断投影区域。

“ 激活安全平面” 勾选激活安全平面在生成节点程序时自动激活程序中该节点之前定义的安全平面。

“ CAD 全屏” 是 CAD 视窗全屏显示。

2.用手操器控制机器, 手动在工件上采点, 动态点界面中显示实测与理论之间的偏差值,元素名称中显示对应的动态点名称, 同时这个点的位置和矢量方向也在模型上显示出来, 同时生成测量结果及程序。

3.测量结束后, 退出动态点界面。

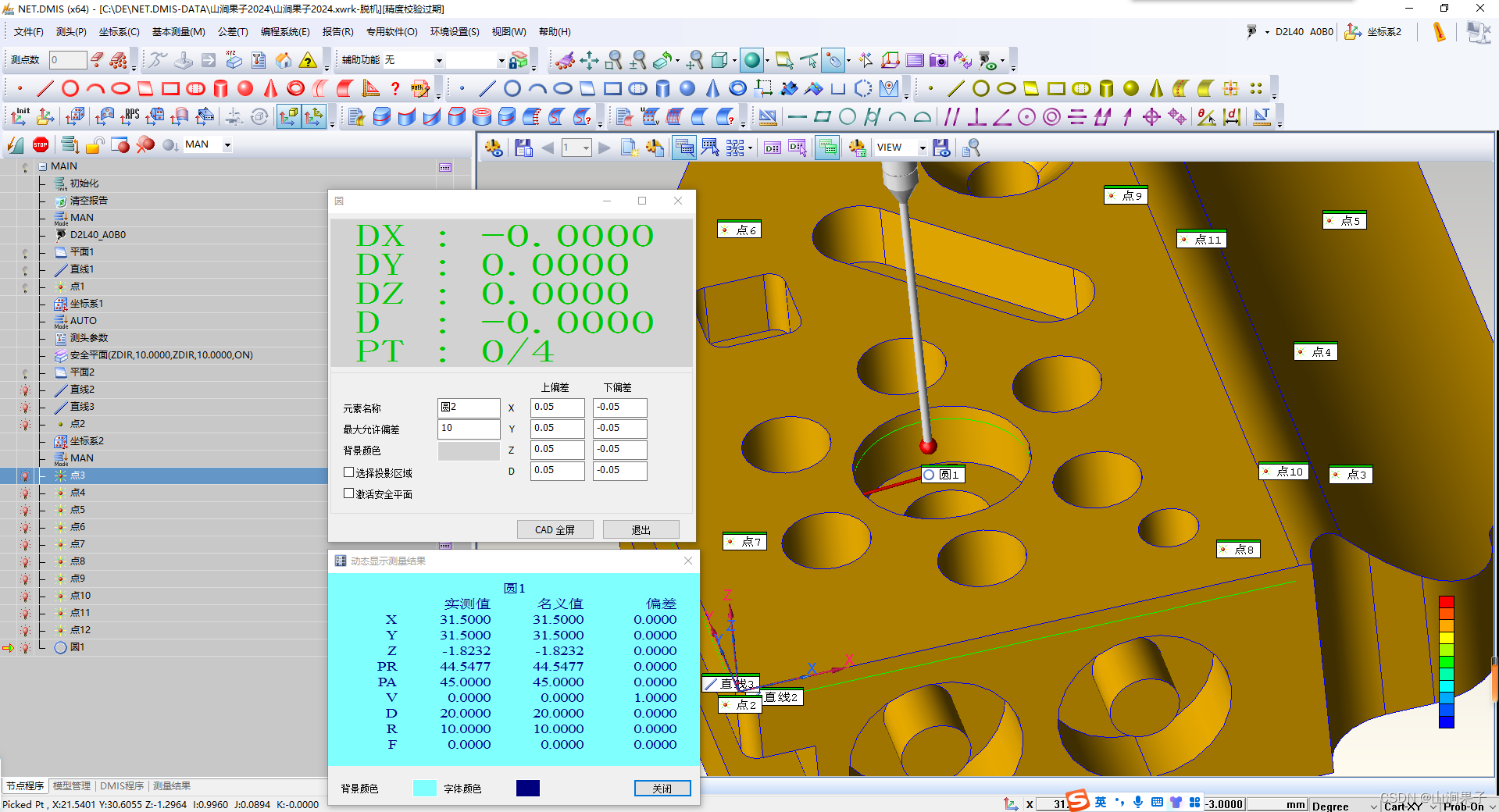

2. 动态圆

通过手动采点, 以第一点的高度位置查找一个理论圆作为测量圆的理论值, 将测点投影到该理论圆上生成实测圆与理论圆对比。

SNSET/DEPTH,0

GEOALG/CIRCLE,LSTSQR

DMESW/COMAND,'CONST/SET_PROJ_VEC,FA(NULL),2'

F(圆1)=FEAT/CIRCLE,INNER,CART,31.5000,31.5000,-1.8232,0,0,1.000000,20.0000

MEAS/CIRCLE,F(圆1),4

PTMEAS/CART,30.6340,41.4624,-1.8232,0.086599,-0.996243,0

PTMEAS/CART,41.1407,34.1566,-2.6378,-0.964067,-0.265658,0

PTMEAS/CART,31.4591,21.5001,-1.8917,0.004089,0.999992,0

PTMEAS/CART,21.5401,30.6055,-1.2964,0.995992,0.089446,0

ENDMES

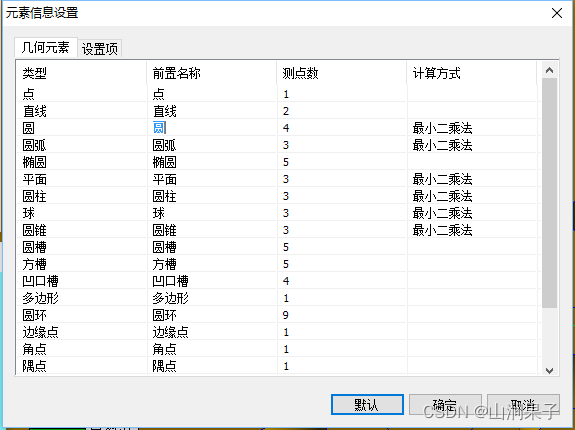

测点个数可在元素信息设置中自定义

最后

以上就是落后墨镜最近收集整理的关于NETDMIS5.0检具实时比对测量2023的全部内容,更多相关NETDMIS5内容请搜索靠谱客的其他文章。

发表评论 取消回复